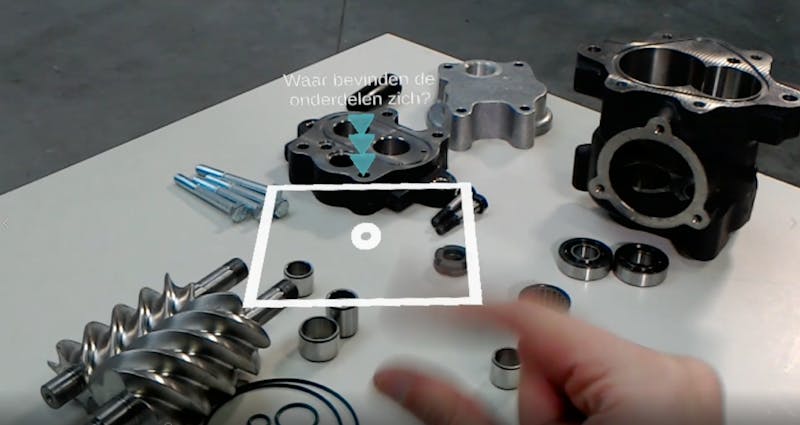

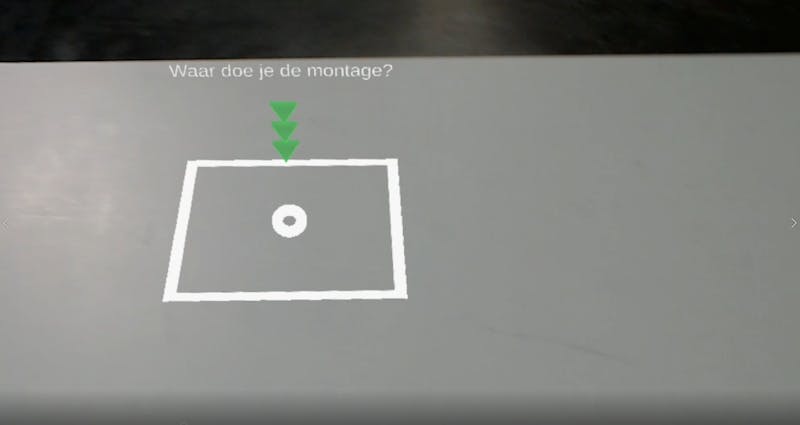

When the trainee puts on the HoloLens, he is no longer on his own. Throughout the assembly process, he is guided by a floating 3D representation of the components and the steps to take. What to pick up next, how to inspect it, how to prepare it, and how and where to mount it.

Using Bluetooth and the appropriate measuring devices like calipers or thickness gauges, the measurements are automatically and wirelessly gathered by the HoloLens, and immediate feedback is given if the measured data are out of spec. This eliminates picking errors that lead to problems later on in the process.

Although current devices do not allow for prolonged use on a real assembly line, they are ready for primetime in procedural learning, such as in this application.